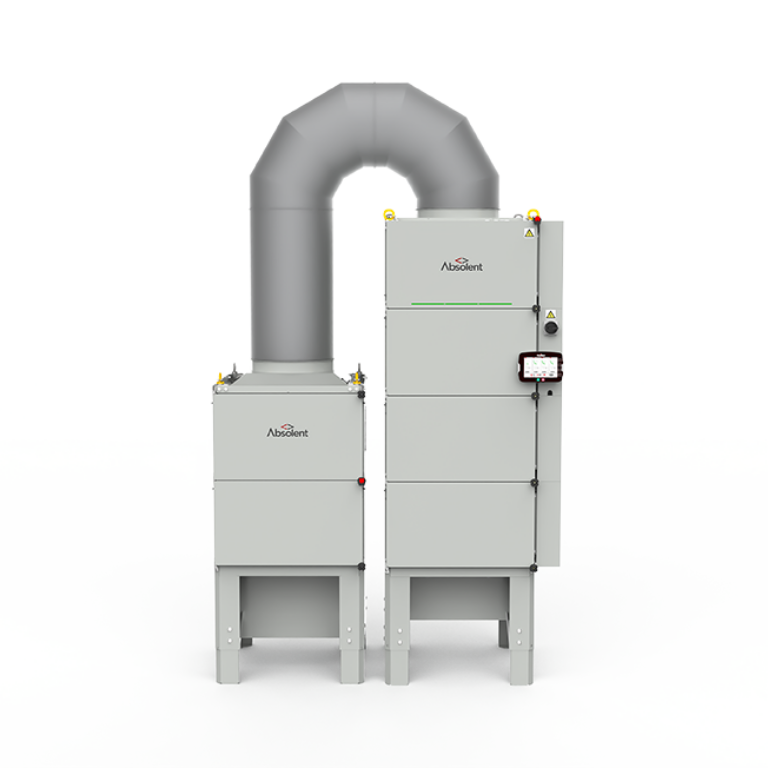

Heat Exchanger

Better indoor environment

A heat exchanger can be used to recover energy and reduce heating costs. Absolent heat exchangers are developed for Absolent’s filter units, and provide customised, complete solutions that are assembled on site which both clean the air and save energy. This is important not least in countries where there is a legal requirement for process air to be expelled from the building.

Energy savings of up to 80%

Production processes often generate heat, and a heat exchanger allows this heat to be returned to the system in an energy-efficient way. The heat exchanger recovers heat from the exhaust air by heating the incoming outside air. In winter, the heat exchanger can recover up to 80% of the heat from the outgoing air, which would otherwise have been lost.

Relative humidity and odor

In industrial environments, it can be difficult to achieve balanced ventilation, usually because the property’s ventilation system is not adequately dimensioned for rooms that are filled with machines and workshop equipment. This can cause the indoor environment to become humid and unpleasant, even if the air is clean and particle-free. A heat exchanger introduces new air, which balances the particle-free process air in your workshop.

Cooling in summer

A heat exchanger does not only help to save heat energy in winter. If the temperature is higher indoors than outside in summer, a heat exchanger can also help lower the indoor temperature by a few degrees. To achieve an even cooler temperature, cooling batteries are available as an accessory.

A heat exchanger can be used to improve the indoor environment, save energy, or to prevent process air from being recirculated if this is a legal requirement. A countercurrent heat exchanger is a safe option if the outgoing and incoming air flows must be kept 100% separate. Air flows should be kept completely separate if, for example, a process generates odors or toxic gases. Countercurrent heat exchangers have a high efficiency rating but usually require defrosting.

Integrated control equipment, EC fan as standard and filtered outside air via approved, rated bag filters. Available in various sizes to meet flow requirements between 2,000–24,000 m3. Absolent heat exchangers and filter units provide a complete solution that is both cost-effective and energy-efficient.

| Range | Metric Measurment | Suitable filter units |

|---|---|---|

| HER20R | 1100cm x 1889cm | A•mist20 / A•smoke20 |

| HER40R | 1500cm x 2289cm | A•mist40 / A•smoke40 |

| HER80R | 1735cm x 2523cm | A•mist80 / A•smoke80 |

| HER120R | 2110cm x 2827cm | A•mist120 / A•smoke120 |

| HER160R | 2430cm x 3219cm | A•mist160 / A•smoke160 |

| HER240R | 2700cm x 3417cm | A•mist200-240 / A•smoke200-240 |