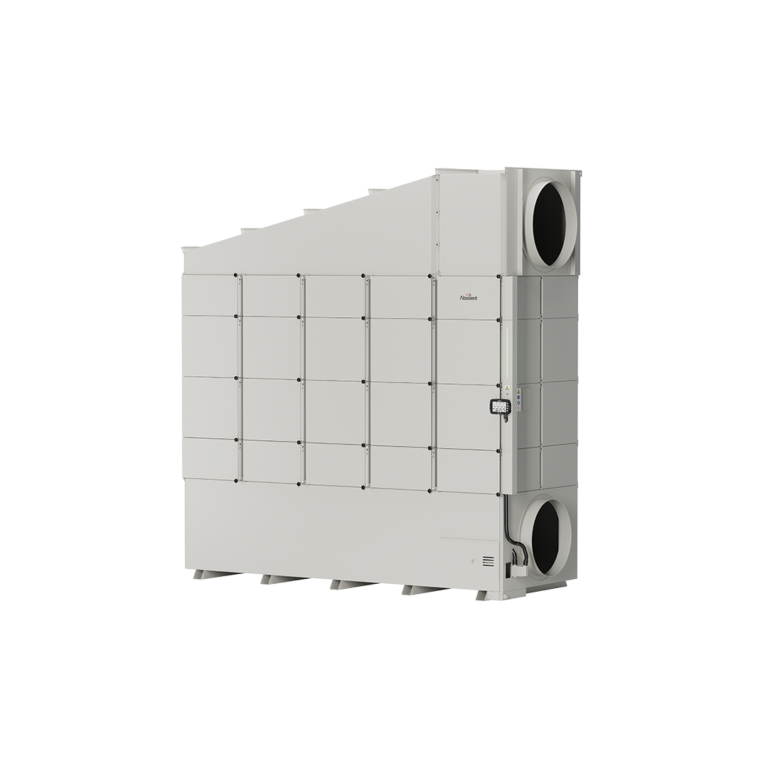

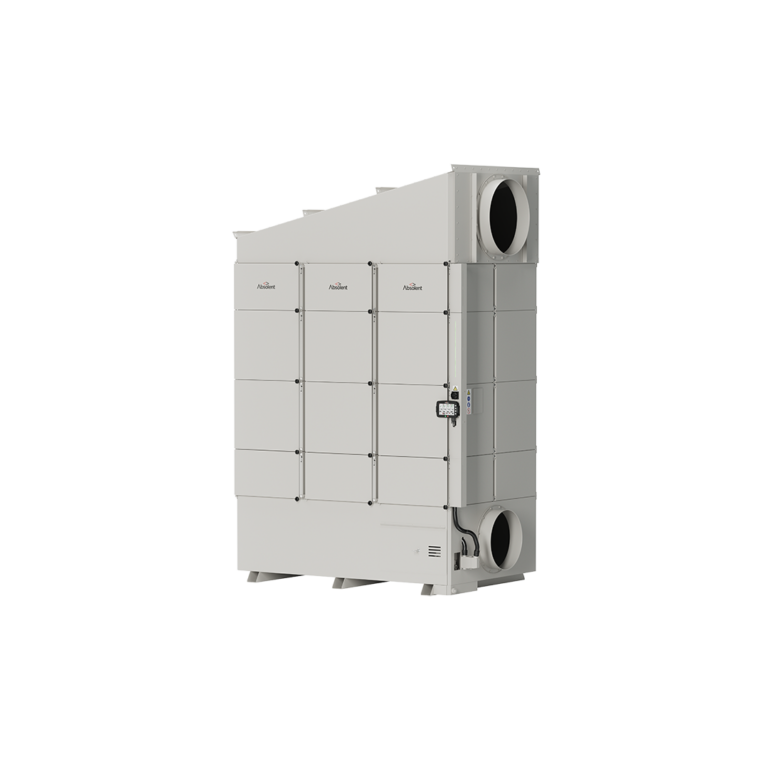

AE200-150 Oil Smoke Filter

AE200-150 offers additional customization options to enhance efficiency and reliability, including:

- Prefilters for sticky particles, optimizing filtration performance

- Airflow measurement for precise system monitoring

- Remote IoT monitoring to enable predictive maintenance, faster diagnostics, and lower maintenance costs

Built for continuous operation and available with IP55 protection, AE200-150 ensures safe, dependable performance whether installed indoors or outdoors.

Unmatched filtration power density - delivering high performance in a compact footprint.

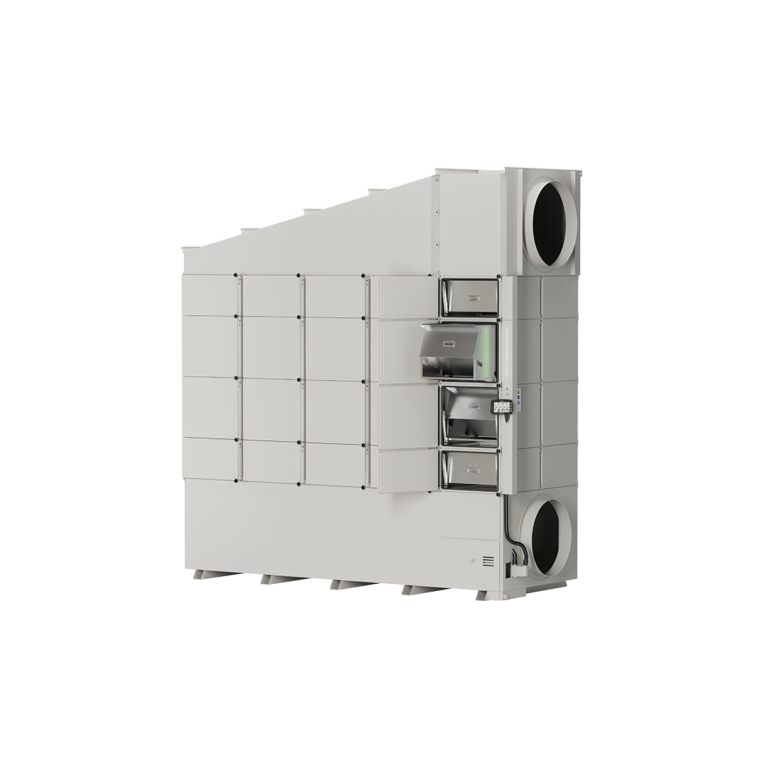

Tilted Multi-Stage Filter Bed – efficiently captures oil smoke and extends filter life.

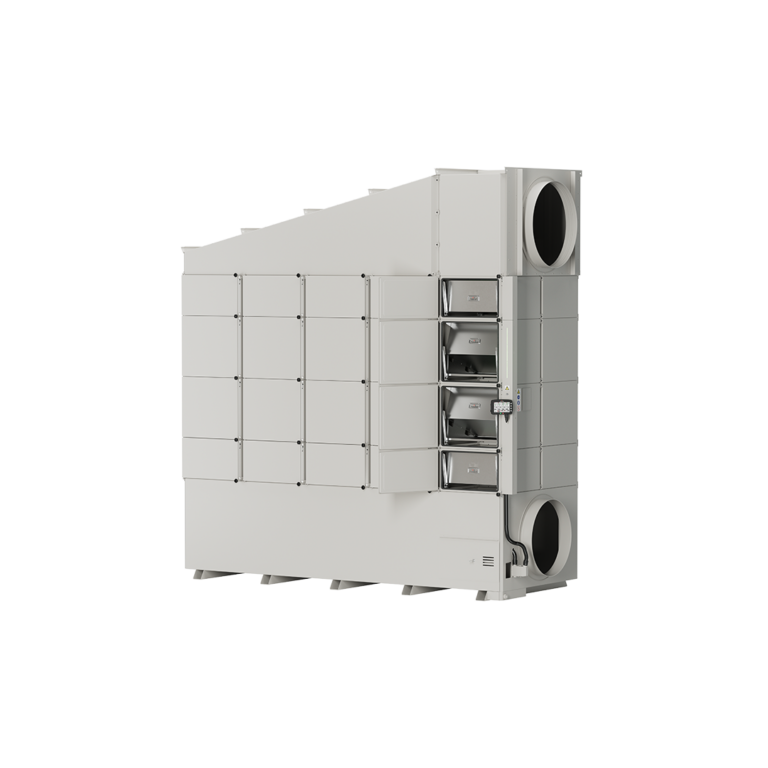

Fast, predictable maintenance - with IoT monitoring and more convienient size of filter cassettes.

EcoDrive™ Technology - dynamically adapts airflow to demand, optimizing energy efficiency and reducing costs.

The fan system is controlled by EcoDrive™, which regulates the external AC fan via a variable frequency drive (VFD). EcoDrive™ continuously adjusts fan speed to match actual process conditions. This maintains stable system pressure and reduces energy consumption without compromising capture performance. The control setup supports post-run settings for optimised operation, multi-machine signal control for seamless integration, and optional vibration monitoring.

Inside AE200-150, the contaminated airflow passes through a tilted 4-stage filter bed where particles are progressively captured and separated. As liquid aerosols are collected, they coalesce and drain through Catch & Release®, routing the recovered liquid to the bottom of the unit. From there, the liquid can be returned to the process or collected in a separate container. The final stage is a HEPA H13 filter that removes 99.95% of airborne particles, ensuring the cleaned air leaving the unit is safe for recirculation.

AE200-150 uses conveniently sized filter cassettes designed for easy, tool-free handling. This keeps maintenance straightforward and downtime predictable.

| Technical Information | Metric | Imperial |

|---|---|---|

| Application | Machining, grinding, die casting, forming/pressing | Machining, grinding, die casting, forming/pressing |

| Nominal airflow | 20 000 m3/h | 11 770 cfm |

| Particle load | 150 mg/m3 | 150 mg/m3 |

| Fan energy class | IE5 | IE5 |

| Fan motor type | AC | AC |

| No. filter cassettes | 40 | 40 |

| Prefilter | Yes, as option | Yes, as option |

| Height | 3 988 mm | 157.3 in |

| Width with accessories/options | 3 863 mm | 153.3 in |

| Depth | 1 490 mm | 58.66 in |

| Inlet Duct Ø | 400 mm | 15.8 in |

| Weight, empty cassettes | 2 503 kg | 5 518 lb |

| Weight, full cassettes | 2 953 kg | 6 510 lb |

| Weight, without cassettes | 1 653 kg | 3 644 lb |