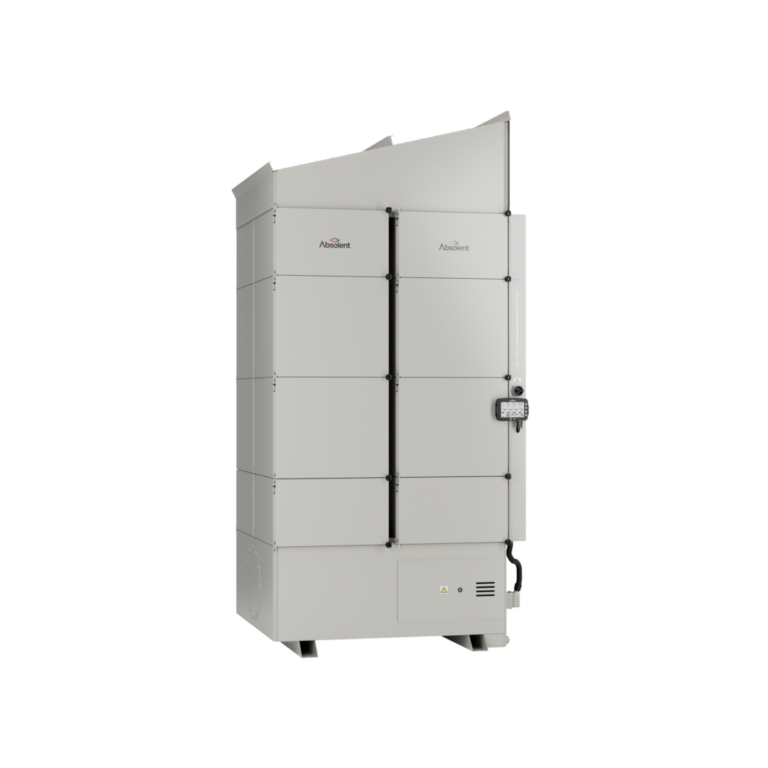

AE80-250 Oil Smoke Filter

AE80-250 is engineered for the heaviest oil smoke applications, where uptime is critical and polluted air is not an option. The powerful filter unit features a tilted four-stage filter bed with HEPA H13 filters that capture 99.97% of airborne particles. Catch & Release technology automatically drains oil to extend filter life. EcoDrive® optimizes airflow to the process, reducing energy use while maintaining performance. Quiet, reliable, and easy to service, AE80-250 keeps production running clean and uninterrupted.

AE80-250 is a high-performance oil smoke filter unit, designed with a tilted 4 stage filter bed technology to ensure efficient drainage, extended filter life, and optimized airflow. The innovative tilted design enhances usable surface area while minimizing footprint, delivering unmatched filtration power across various airflow demands.

AE80-250 offers additional customization options to enhance efficiency and reliability, including:

- Prefilters for sticky particles, optimizing filtration performance

- Airflow measurement for precise system monitoring

- Remote IoT monitoring to enable predictive maintenance, faster diagnostics, and lower maintenance costs

Built for continuous operation and available with IP55 protection, AE80-250 ensures safe and dependable performance whether installed indoors or outdoors.

Unmatched filtration power density - delivering high performance in a compact footprint.

Tilted Multi-Stage Filter Bed – efficiently captures oil smoke and extends filter life.

Fast, predictable maintenance - with IoT monitoring and more convienient size of filter cassettes.

EcoDrive™ Technology - dynamically adapts airflow to demand, optimizing energy efficiency and reducing costs.

The unit supports:

- Post-run settings for optimized operation

- Multi-machine signal control for seamless integration

- Optional vibration monitoring for added reliability

Each unit is equipped with convienint sized filter cassettes, designed for manual handling, eliminating the need for tools or lifting equipment.

| Technical Information | Metric | Imperial |

|---|---|---|

| Application | Machining, grinding, die casting, forming/pressing | Machining, grinding, die casting, forming/pressing |

| Nominal airflow | 8000 m3/h | 4709 cfm |

| Particle load | 250 mg/m3 | 250 mg/m3 |

| Fan energy class | IE5 | IE5 |

| Fan motor type | AC | AC |

| No. fans | 1 | 1 |

| Sound level 75% (normal operation) | ||

| Sound level 100% | ||

| No. filter cassettes | 16 | 16 |

| Prefilter | Yes, as option | Yes, as option |

| Height without extension legs | x mm | x inch |

| Width with accessories/options | 1620 mm | 63.8 in |

| Depth | 1468 mm | 57.8 in |

| Inlet Duct Ø | 400 mm | 15.8 in |

| Weight, empty cassettes | ||

| Weight, full cassettes | ||

| Weight, without cassettes |