La gamma A•smokeFood è stata sviluppata pensando al cibo. A•smoke20Food dispone di uno dei sistemi più efficaci al mondo per la pulizia di nebbie oleose e fumi oleosi. È progettato per la gestione di applicazioni impegnative nell’industria alimentare con temperature fino a 90°C (200 F) e flussi d’aria fino a 2.000 m³/h. Quando sono richieste temperature più elevate, si consiglia di diluire l’aria per ridurre la temperatura.

6 barili di olio

Niente più pavimenti scivolosi e ambiente lavorativo con aria sporca. In un anno raccogliamo 6 barili di olio. Nell’aria ne rimane solo un cucchiaino.

Aria pulita - sempre

Il filtro HEPA H13 garantisce aria pulita, sempre.

8760 ore di funzionamento

Quattro stadi filtranti catturano tutte le particelle, offrendoti un anno di funzionamento senza manutenzione.

Per utilizzo

Extremely low maintenance

Absolent filter units usually run for at least one year without requiring a filter change. This results in a low total cost of ownership.

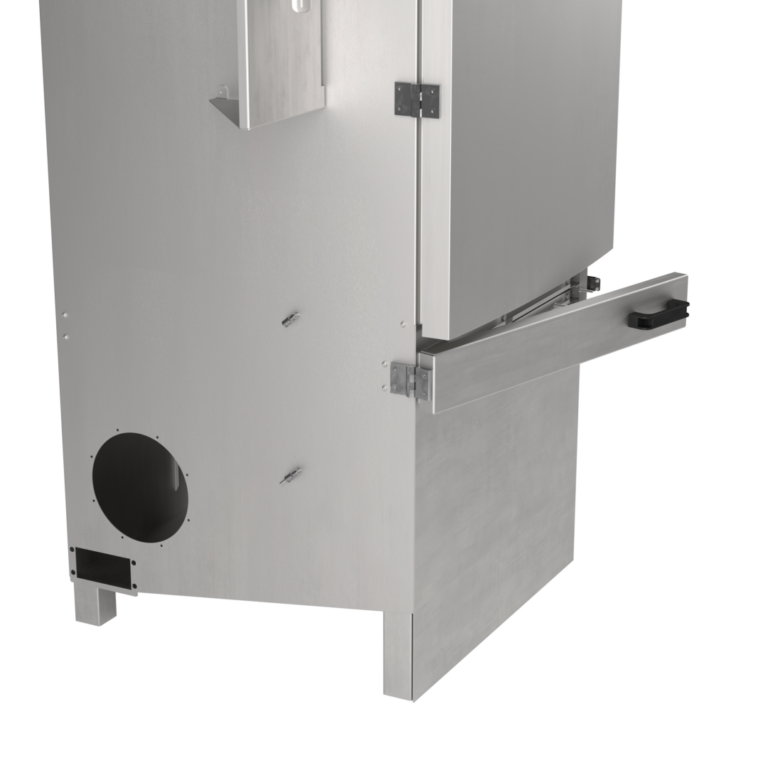

Build for durability

A•smoke20Food is primary made of acid proof stainless steel (1.4404) with durable food application connections. It is built to withstand temperatures of 90°C (200 F). The smart sloped design of the air intake unit enables easier oil and water drainage. Thanks to the continuous draining of the filter cassettes, the unit can be operated without interruptions. The return oil can be collected at the bottom of the filter for recycling or disposal.

The unit comes with pre-filter as standard with separate compartment for ease of change during operation. Removable filter tension system for better wash down opportunities. When higher temperature demands are required, we propose normally to dilute the air to reduce the temperature.

The filtering process

The process air passes through a self-draining Absolent filter cassette. Here, the bigger particles of the oil mist and smoke are captured. When the filter is saturated, the liquid drops into the return oil tank. The air continues through the next Absolent filter, where the mid-size particles are captured. The third stage consists of a HEPA13 filter, with stainless steel frame. The HEPA13 has a guaranteed and consistent collection efficiency of 99.97% capturing 0.3μm dia. particles.

Special equipment & options

A•smoke20Food has analogue pressure gauges for each filter stage that indicate when a filter change is necessary. The pressure gauges are all designed to handle 90°C (200 F) as a standard. The unit is also equipped with condensation traps to ensure no oil or water can accumulate in the tubes or get into the gauges. When there is a risk of cooking oil and grease solidifying there is a heated option available to prevent clogging of the filter element or the draining solution. If pump solution is needed for drainage, there is an option of a pump with food safe components and special impeller capable of withstanding the demanding atmosphere.

| Technical Information | Metric | Imperial |

|---|---|---|

| Height | 2265 mm | 89.2 in |

| Width | 700 mm | 27.6 in |

| Depth | 775 mm | 30.5 in |

| Weight, dry filter cassettes | 362 kg | 798.1 lbs |

| Max. Airflow | 2000 m³/h | 1180 cfm |