Centralized Oil Mist Filters with Fan

The Absolent type A•mist Oil mist filter features one of the most effective systems in the world for cleaning oil mist. The series of central filter units consists of parallel modules which are dimensioned after the needed air-flow. The advantages of central filters are a cheaper installation, easier service because of less service points and the possibility to lead the process air through a heat exchanger. Lead for example the process air outside during summer and back into the premises at winter time.

3 OIL BARRELS

No more slippery floors and dangerous mist. Only 2.5 teaspoons per year remain. And clean air!

CLEAN AIR - ALWAYS

The HEPA H13 filter guarantees clean air – always. Only the best is good enough!

8760 RUNNING HOURS

Our unique filter cassettes capture all particles – giving you 1 year of maintenance free operation.

The highest possible collecting efficiency

The filtered air becomes so clean that it usually can be returned to the premises. This means less loss of energy and a more balanced ventilation.

Extremely low maintenance

Absolent filter units can usually run for at least one year without requiring a filter change. Moreover, A•mist filter cassettes can usually be washed**. This results in a low total cost of ownership.

A very reliable filter unit

The fan, as the only moving component, is placed at the clean-side to minimize wear & tear.

Functional Design

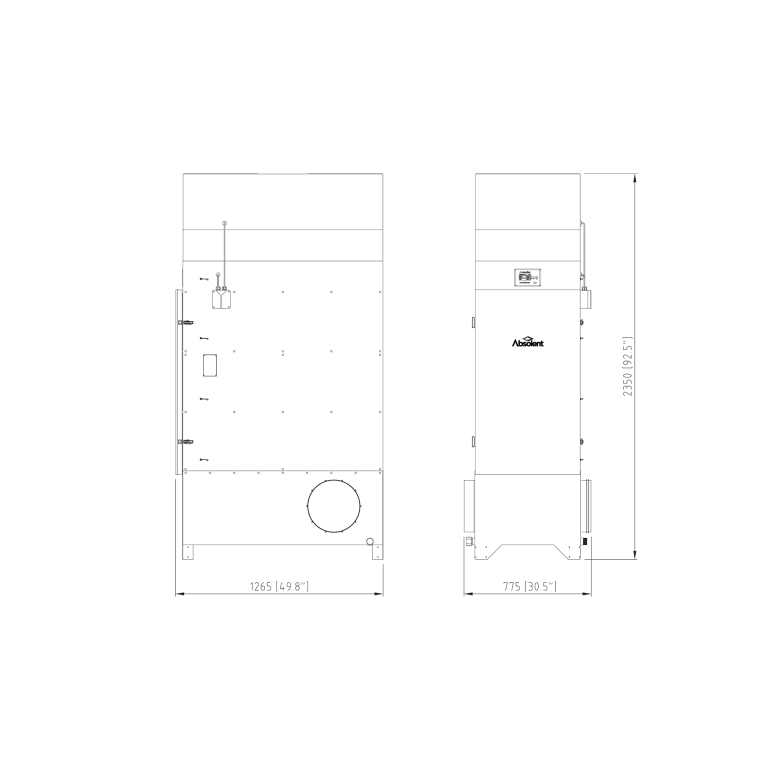

The A•mist filter range has a highly robust tower design that occupies a minimum of floor space. Its hinged access doors make service still more convenient. The filter is supplied with a baked powder painted finish that adds colour to the shop floor.

Operation

The filtering process occurs in three stages. The first and second stages consist of self-draining Absolent filter cassettes. The third stage consists of a HEPA-filter, which has a guaranteed and consistent collecting efficiency of 99.97% arresting 0.3μm dia. particles. The filter unit has an electronic pressure gauge, A•monitor, which shows the pressure drop over the different filter stages and indicates when a filter cassette is to be changed. Thanks to the continuous draining of the filter cassettes, the unit can be operated without interruptions. The return oil is collected at the bottom of the filter for recycling.

| Technical Information | Metric | Imperial |

|---|---|---|

| HEIGHT | 2360 mm | 92.9 in |

| WIDTH | 723 mm | 28.5 in |

| DEPTH | 1267 mm | 49.9 in |

| INLET DUCT Ø | 315 mm* | 12.4 in* |

| WEIGHT WITH DRY FILTERS | 385 kg | 840 lbs |

| Motor Output | 4.0 kW | 5.4 hp |

| MAX. PERMISSIBLE AIR VOLUME | 4000 m³/h | 2350 cfm |

| TYPICAL OIL values FOR THIS FILTER/YEAR | ||

| Oil quantity, IN | 3.1 barrels/yr | 3.1 barrels/yr |

| Oil quantity, OUT | 2.5 tsp/yr | 2.5 tsp/yr |

*INLET DUCT NOT INCLUDED FOR THE US MARKET. **Not applicable to HEPA filters